Home>Products>seeds nuts shellers>High efficiency sunflower seeds deshelling machine

High efficiency sunflower seeds deshelling machine

- Qiaopai

- Liaoning, China (Mainland)

- ISO9001 & CE

- 1 Set/Sets

- US $10,000 - 28,000/ Set

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 60 Set/Sets per Month

-

seeds dehulling2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

seeds dehulling2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Details

| Condition: | New | Type: | agro-machinery | Use: | dehulling for sunflower seeds |

| Production Capacity: | 1000-1500kg/hour | Place of Origin: | Liaoning, China (Mainland) | Brand Name: | Qiaopai |

| Model Number: | TFKH1500 | Voltage: | 380V | Power(W): | 16.47KW |

| Dimension(L*W*H): | 11.3m*3.3m*5.5m | Weight: | 7mts | Certification: | ISO9001 & CE |

| Warranty: | 1 year | After-sales Service Provided: | Engineers available to service machinery overseas | Input capacity: | 1.0-1.5mt/hour(varies with raw materials |

| % of whole kerenls: | 90% minimum . |

Product Description

Specifications

1.CE ISO 9001:2008 & TUV certified2.4-dehullers design vertical

3.equipped with frequency inverter and patented product

Sunflower Seeds Dehulling & Separating Equipment TFKH1500

[Functions and Features]

sunflower seeds dehulling & separating equipment Model TFKH1500 is a patented product of Qiaopai company and is the independent intellectual property of Qiaopai company. It contains 7 national patents. This equipment can dehull sunflower seeds, separate shells from kernels and re-separate your products. It adopts exclusive design: multiple dehullers, vertical set-up with wide separating screens to make the dehulling and separating more efficient and meanwhile save more space.it features low loss of materials and easy maintenance.

Vertical dehullers set-up You can achieve ideal separating Wide-screen design increase

design save space result by adjusting angle of screens the separation capacity

Pneumatic device for back-flowing materials Dehullers adopt all-steel main parts, the

makes the un-dehulled sunflower inshell flow back impeller adopts 99% alumina porcelain

to dehullers automatically. improves the dehulling result and

gives longer service time.

Adopt shells-discharger to make the sunflower Perforated screen plate make seed-kernels

shells collecting works easier and meanwhile separation works easier, which made from

reduce the dust accumulation greatly during punching works of premium quality cold

process. rolled sheet,durable service.

All the electric works of this equipment are central Vibration source of the equipment adopts

controlled by electric control cabinet, interface is vibratory motors design,features easy and

easy operation. The application of frequency quick installation no foundation works requires

technique in dehullers can adjust the frequency

rate anytime according to the state of materials.

[ Component]

It consists of input hopper(1), spiral elevator (2), multi-functional cleaner (3),bucket elevator (4), 4-dehullers (5), pneumatic device for back-flowing materials (6), reseparator (7), kernels collector (8), electric control cabinet (9).

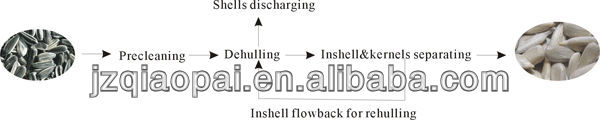

[Process]

[Technical parameters]

Power: 16.47kw(380v)

Input capacity: 1.0-1.5mt/hour(varies with raw materials)

% of whole kerenls:90% minimum

(kernels that are less than 1/2 whole kernels are brokens)

% of inshell in final kernels: 2-5%

Space occupied: 11.3m×3.3m

Height:5.5m

Weight:7.0mt

Contact Us

- seeds dehulling

- Address107, Beiguan District, Anyang City

- Phone(Working Time)86-0372--3931234

Product Categories

- Oil Refinery Equipment

- shellers

- seed dehulling machine

- seeds nuts shellers

- dehulled hempseeds kernels

- hulled hemp seed

- organic hemp protein

- Agriculture Machine & Equipment

- Peeling Machine

- Feed Machine

- sheller and huller machine

- packing machine

- oil press and complete oil equipment

- Oil and Beverage Machinery

- Home&School Product Making Machinery

- Oil Press Machine

- Microwave Drying And Sterilizing Equipment

- Microwave Vacuum Drying Equipment

- Microwave Extracting Equipment

- Microwave Oven

- Agricultural and Sideline products dryer

- Seafood dryer sterilizer

- Spices Dryer Sterilizer

- Tea Dryer Sterilizer

- Nut Roasting Machine

- Ready Meal Heating Equipment

- Microwave food products drying equipment

- Microwave Herb Drying Sterilization Equipment

- Microwave equipment

- Microwave Medical Products Sterilization Equipment

- Chemical Material Drying Sterilization Equipment

- Paper Products Microwave Drying Equipment

- Hot air dryer & Roaster

- Microwave Heating Equipment

- Microwave wood products drying equipment

- Microwave Sterilizing Equipment

- Microwave Roasting Equipment

- Microwave Equipment Spare Parts

- food progress equipment

- Microwave Dryer

- Drying Oven

- Industrial microwave oven

- Microwave Oven Dryer

- Oil Press Machinery

- Drying Equipment

- rice hulling machine/rice sheller

- corn sheller/corn thresher

- Nut Processing Machine

- sunflower seed shelling machine

- palm shelling machine

- Walnut sheller&seperator

- Nut&Seed Processing Machinery

- Oats dehulling and separating equipment

- watermelon seeds dehulling and separating equipment

- Job's tears dehulling and separating equipment

- Tartary buckwheat dehulling and separating equipment

- Silybum marianum dehulling and separating equipment

- Foxnut dehulling and separating equipment

- Hempseeds dehulling and separating equipment

- Mung beans decorticating and separating equipment

- Peanut Butter Production Line

- Almond/Peanut Peeling machine

- Pinenuts dehulling and separating equipment

- Rubber seeds dehulling and separating equipment

- Castor bean dehulling and separating equipment

- Rapeseeds dehulling and separating equipment

- Agricultural Instrument

- Oil Plant

- Walnut shelling equipment

- Barley Dehuller and separating equipment

- Perilla seed Dehuller and separating equipment

- Buckwheat Dehulling Machine

- Pumpkin seeds dehulling and separating equipment

- Apricot kernel shelling machine

Hazelnut Almond Dehuller Sheller Cracking Machine

Hazelnut Almond Dehuller Sheller Cracking Machine Destoner for Cherry Plum Fruit seed remove machine

Destoner for Cherry Plum Fruit seed remove machine apricot destoner seed removing machine

apricot destoner seed removing machine Destoner for Cherries, Apricots, plums

Destoner for Cherries, Apricots, plums Small Almond and hazelnut walnut sheller Cracker

Small Almond and hazelnut walnut sheller Cracker